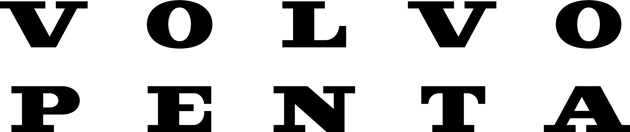

Final result mounted on a two-metre inflatable rubber boat.

Future waves

As small-scale water mobility evolves towards cleaner and more innovative solutions, this project introduces a modular electric outboard system designed specifically for dinghies and tenders. The design divides the system into three primary components: a lightweight motor module, two compact battery units, and a connecting mounting bracket that also functions as an electrical connection. The foldable motor is permanently attached to the boat, streamlining day-to-day use and transport. With a battery runtime of up to one hour at full throttle and approximately ten hours under standard conditions, the system supports typical recreational and utility applications. Integrated with Volvo Penta’s Easy Connect app, the motor provides personalised driving modes and GPS-based safety features—enhancing control and user confidence on the water. Minimal in form and modular in function, the system is designed with future technological advancements in mind and aims for market readiness within 3–5 years.

Project Information

As water-based mobility increasingly shifts towards sustainable and user-friendly solutions, this thesis project explores a modular electric outboard system designed for small boats such as dinghies and tenders. The aim is to develop an efficient and accessible alternative to traditional combustion engines—one that reduces emissions, simplifies handling, and embraces digital connectivity. Central to the design is a three-part architecture: a lightweight electric motor module, two compact battery units, and a universal mounting bracket that facilitates both physical attachment and power transfer.

Unlike conventional outboards, the motor is foldable and designed to remain permanently attached to the dinghy, eliminating the need for frequent mounting and dismounting. This enhances usability for casual boaters and reduces wear over time. To bridge the gap between analogue boating and connected systems, the concept integrates with Volvo Penta’s Easy Connect app, enabling GPS-based safety tracking and customisable driving profiles—features typically reserved for larger marine systems. The project aims to make sustainable marine propulsion more accessible while laying the groundwork for future expansion in a rapidly evolving market.

Methods

The development process began with an analysis of current market offerings, revealing a lack of modular, sustainable solutions tailored to the specific needs of small-scale boat users. I conducted a technical review of emerging battery technologies, focusing on realistic capacities and load profiles to inform runtime expectations—targeting one hour at full throttle and up to ten hours in standard use.

Design research included benchmarking existing electric outboards, evaluating marine use cases, and examining principles of modularity and user-centred design. I created iterative prototypes to refine the system layout, motor folding mechanism, and user interaction with the modular components. A strong emphasis was placed on weight distribution and form factor to ensure that the battery, housed separately inside the dinghy, would enhance balance, improve ergonomics, and streamline the motor design.

The connection with the Volvo Penta Easy Connect app brings enhanced features like personalised driving modes and GPS-based safety functions. This integration seamlessly links physical hardware with digital control, incorporating the tender into the primary boat's interface, elevating it from a minor standalone object to an integral part of the system.

Designed with long-term viability in mind, the system provides a flexible foundation for future iterations as battery technology advances. By combining sustainable engineering with intuitive design and smart connectivity, the project offers a forward-thinking alternative to traditional outboards—suited to a generation of users who expect more from marine mobility.

Result

The final concept is a clean, compact, and modular electric outboard system that redefines what propulsion can look like for small boats. The foldable motor remains attached to the transom and connects to the two compact battery units via a custom bracket that ensures mechanical and electrical alignment. The separation of motor and battery reduces rear weight, increases onboard space, and simplifies handling, making the system ideal for recreational or short-range transport use.

The battery unit meets typical boating needs with up to ten hours of runtime under standard conditions. Its location inside the dinghy enhances balance and ensures compatibility with future modular upgrades. The integrated connection to the Volvo Penta Easy Connect app introduces advanced features such as personalised driving modes and GPS-based safety functions, bridging the gap between physical hardware and digital control.

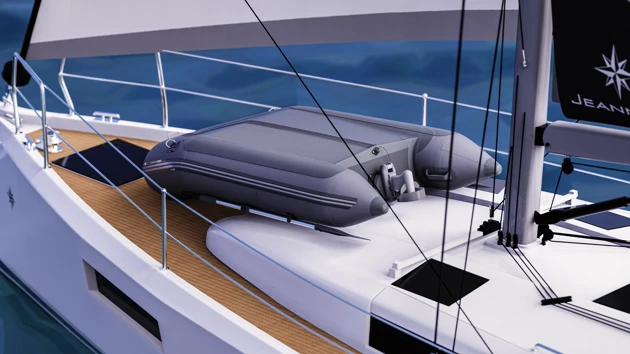

The dedicated charging station is designed to fit seamlessly into the stern of the leading boat—where a traditional combustion engine for the tender would typically be stored. It features an integrated slot for securely placing the motor key, as well as an option to store the tiller when not in use. A built-in solar panel, positioned for continuous sun exposure, efficiently charges both battery modules. A small front-facing window provides a clear view of the batteries inside, allowing users to easily check their presence and charging status at a glance.

Designed with long-term viability in mind, the system offers a flexible foundation for future iterations as battery technology advances. By combining sustainable engineering with intuitive design and smart connectivity, the project presents a forward-thinking alternative to traditional outboards—suited to a generation of users who expect more from marine mobility.

In collaboration with:

UID25 | Ellis Walker – Grad project presentation

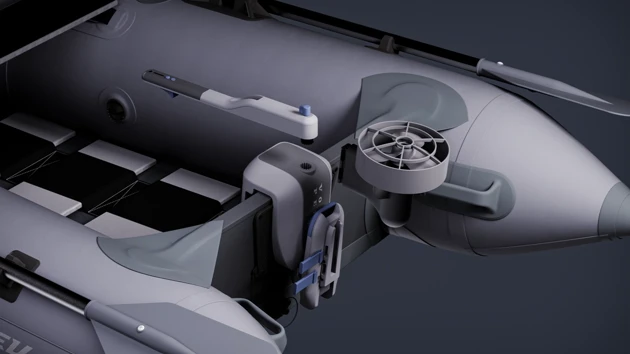

Assembly of the motor unit and tiller.

Inserting the two compact battery units.

Storing the motor to store the tender.

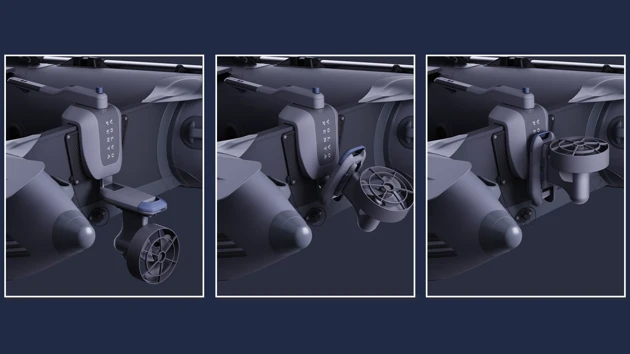

Tender stored on the leading boat with the motor module attached.

Selecting the driving modes which can be configured in the Volvo Penta Easy Connect App.

Inserting the battery into the charging station. Attaching the tiller to its designated slot in the charging station.

Charging station attached to the leading boat’s stern pulpit.

Process: Exploring dimensions and ergonomics with styrofoam mock-ups.