The result

Handy picking system

This bachelor's thesis project focuses on improving the picking system within food warehouses. The project addresses challenges with the current pick-by-voice system, which often causes errors, communication issues, and reduces social interaction among workers. Through extensive user research including warehouse surveys, eight interviews with users, and observations the key problems were identified, such as voice recognition inaccuracies, user discomfort, and inefficiencies in the workflow. Using the user-centered design approach and the Double Diamond process, the project led to the development of a new concept called Handy Picking: a wearable device featuring an industrial-grade touchscreen in a compact format and haptic feedback. The second component is an attachable device for the jacket, integrating AI support to assist the picking process. The solution aims to enhance picking accuracy, efficiency, and user satisfaction, while contributing to sustainability goals by improving working conditions and minimizing food waste. Materials, form language, and real-world usability were carefully considered through iterative prototyping and user feedback. The project offers a practical, future-ready alternative to the outdated system, combining reliability, adaptability, and user well-being.

Project Information

The thesis project focuses on improving the working conditions and workflow for employees in food warehouses, specifically for those who pick goods from shelves and bring them to the finalization area for delivery to customers using the current pick-by-voice system. This system, while widely used, suffers from various drawbacks such as poor voice recognition, lack of flexibility, and a negative impact on social interaction and user satisfaction. The outcome of the project is a new wearable system that combines a touchscreen device worn on the forearm with a companion AI-powered unit that attaches to clothing. Together, these devices aim to enhance accuracy, communication, and efficiency in the picking process, offering a future-forward alternative to outdated systems by prioritizing adaptability, durability, and an improved user experience. The project not only delivers a tangible product concept but also serves as a foundation for future development in warehouse logistics technology.

Methods

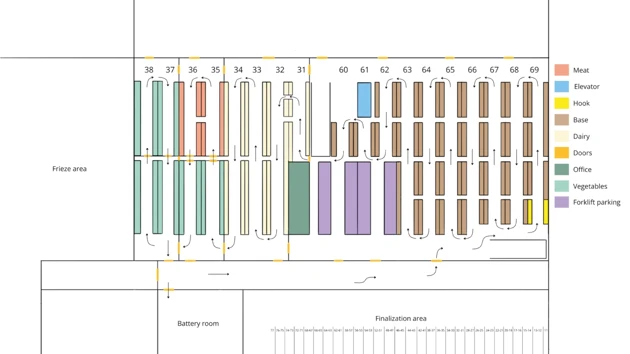

The project was guided by the Double Diamond process. This structure allowed for a clear and iterative progression from identifying the problem to testing solutions with users in real-world scenarios. The initial phase focused heavily on research and users. A food warehouse in Västerbotten served as the primary context, where observations were made and eight warehouse workers of various ages were interviewed. Alongside the interviews, the work environment was mapped out through diagrams, activity analyses, and system mapping to fully understand the picking process. The process emphasized user-centered design, and long-term adaptability, aligning both with workplace demands and sustainability considerations.

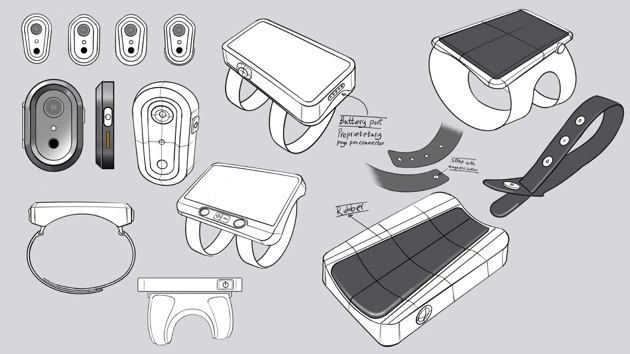

Pitch of the project was presented to a technician at the warehouse who later became an external tutor. Regular check-ins with this tutor ensured feedback from the field guided the process. After the gathered data underwent a function analysis, it helped identify key features needed in a new picking system. With this foundation, ideation and concept development followed. A brainstorming workshop with other design students led to three concepts, which were evaluated with users. Three main concepts were developed in detail, and based on user feedback, a combination of two concepts led to the visual interfaces for the screen. Prototypes of varying sizes were produced and tested on users to ensure comfort and usability for both small and large forearms. Interface layouts were all iteratively developed using both 3D printing and physical testing. User feedback played a key role throughout, ensuring the final concept met real needs in the warehouse environment.

Result

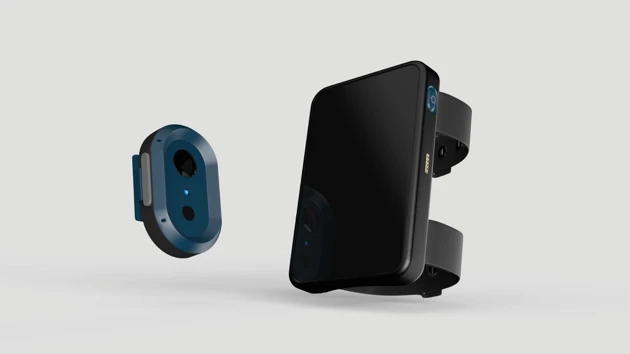

Handy Picking is a dual-device wearable system developed to address the key issues found in the current pick-by-voice system. The solution consists of two

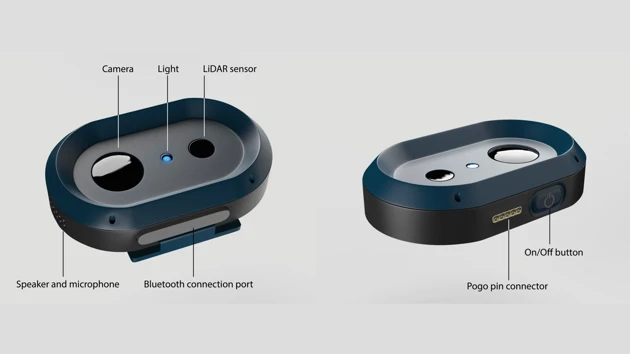

integrated components: a compact industrial-grade touchscreen device worn on the forearm. The two devices communicate via Bluetooth, providing real-time support throughout the picking process. The forearm unit displays task-relevant information in a clear way, with a touchscreen interface designed for use with gloves. It includes haptic feedback for better interaction and a speaker-microphone setup for communication. The wearable device on the clothes contains a camera and AI support that helps verify item quantities, and track actions. This combination improves task accuracy, reduces system errors, and enhances user comfort and efficiency.

UID25 | Hamayon Jafari – Grad project presentation

Touchscreen product that sits on the forearm.

Touchscreen product that sits on the forearm.

Wearable device worn on clothing.

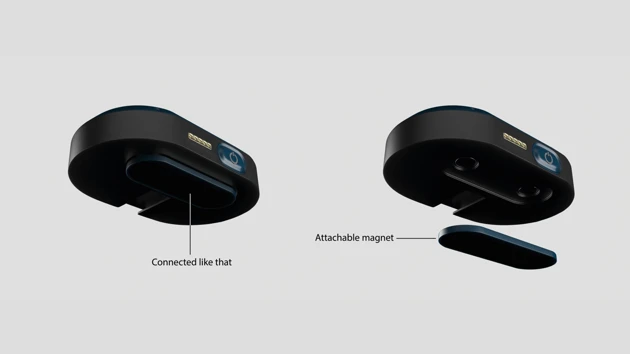

The way to connect to devices together.

The wearable device can be worn on clothing in two ways. The first method is using the attachable magnet, which is suitable when the user is wearing a t-shirt.

The wearable device can be worn on clothing in two ways. The second method is using the hook, which is suitable when the user is wearing a jacket that has a pocket.

How to use the device.

prototypes.

Sketches.

The warehouse layout that was surveyed.